Which Ice Cube Maker Do You Need?

Foodservice operations and hospitality businesses use ice in a variety of ways, even within beverage service. For example, an establishment with a drink menu offering smoothies and sodas would require a different ice cube machine than a bar serving premium cocktails. Because of this, it's important to know which type of ice cube is best suited to your needs.

If your menu calls for poured drinks and mixed beverages, a full-cube ice machine or half-cube ice machine may be most beneficial to your establishment. Below, we'll discuss the differences between these types of ice and the ice cube maker machines that produce them.

Full Cube vs. Half Cube

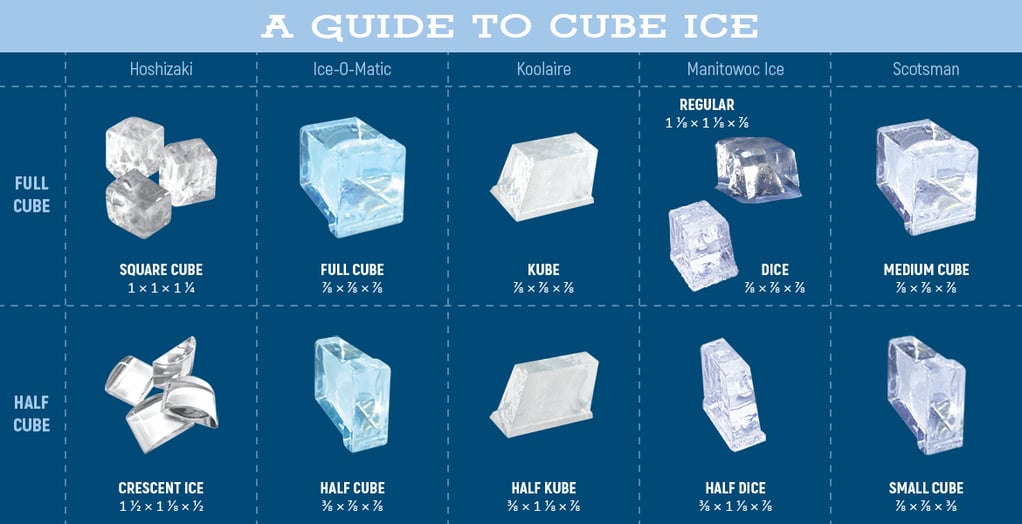

Ice cube makers produce cube ice by running water over a grid, which freezes the water into the shape dictated by the grid's design. The main difference between full-cube and half-cube ice is the size of the grid squares. Each company that manufactures ice cube machines has coined its own terminology for full cubes and half cubes, and each series of machines will make a cube with unique dimensions. These differences are illustrated below.

Most manufacturers' cube ice has a square or rhomboidal shape, but Hoshizaki is known for offering a crescent-shaped cube. Unlike ice that is designed to be chewed easily or used in product displays like nugget and flake ice, cube ice of any design is harder and more versatile.

Half-cube ice has the smallest overall dimensions of the two cube types. That makes it suitable for making blended beverages, from smoothies to frozen cocktails like margaritas, because it blends quickly and easily. If your establishment allows guests to dispense their own ice, half-cube ice machines help ensure consistent and reliable dispensing because the ice is less prone to getting stuck in dispenser chutes.

Its smaller dimensions mean that more of a half cube's mass is exposed as surface area, enabling it to cool drinks quickly. Finally, half-cube ice packs more densely in glasses than full-cube ice, displacing more drink and saving you on drink costs. Although crescent ice has larger dimensions than most half cubes, it is classified as half-cube ice because of the way it displaces beverages.

Full-cube ice is a classic choice for serving a variety of beverages, including sodas, tea, and water. For operators who serve mixed drinks or pours of liquor but do not wish to invest in a specialty ice maker, the full cube's larger size means it can also be used to serve those adult beverages on the rocks. Full-cube ice has the advantage of melting slowly, so it won't water down drinks as quickly as full-cube ice. This versatility can be very useful in restaurants where kitchen space is at a premium and streamlined preparation means quicker service. Full-cube ice is also the ice of choice for bagging operations and other businesses that sell bagged ice, like convenience stores.

Advantages and Disadvantages of Cube Ice

Full Cube Ice

Advantages:

- Larger size

- Melts more slowly

Disadvantages:

- Less drink displacement

- Harder to chew and blend

Half Cube Ice

Advantages:

- Higher drink displacement

- Better for blending

Disadvantages:

- Melts faster

Choosing an Ice Cube Maker

Once you've decided which type of ice cube will best suit your needs, you'll need to decide which type of ice cube maker can be accommodated by your layout and workflow. When choosing an ice cube maker, it's important to consider how much space is available for your ice machine and to check the machine's dimensions, as well as any clearance requirements. However, how your ice cube maker will factor into your workflow will also impact your final decision.

Some establishments need dispensers that can be easily used by guests, while others require ice machines with high-capacity bins that can supply an entire dining room. KaTom offers some guidelines for sizing your commercial ice machine by production capacity, or you can consult the sizing estimates specific to cube ice below.

| Business Type | Estimated Daily Use |

| Restaurant | 1.5 lbs. per customer |

| Cocktail Lounge | 3 lbs. per customer |

| Fast Food | 5 oz. per 7- to 10-oz. drink |

| 8 oz. per 12- to 16-oz. drink | |

| 12 oz. per 18- to 24-oz. drink | |

| Convenience Store – Beverages | 6 oz. per 12-oz. drink |

| 10 oz. per 20-oz. drink | |

| 16 oz. per 32-oz. drink | |

| Convenience Store – Bagging | Calculate lbs. per bag x bags sold per day |

| Healthcare Cafeteria | 1 lb. per person |

The best way to estimate your business' ideal production capacity is to count up the average amount of ice that gets used per seat or per person each day. If you're unsure of which production capacity your establishment requires, it is recommended that you size up instead of down.

Countertop ice machines generally offer the lowest capacities, while ice machine head and bin combos have the highest, but each type of ice machine provides a wide range of production capacities. This will ensure your kitchen is equipped with an ice cube maker that can keep up with demand during your busiest hours.

Countertop ice machines function as dispensers and are generally not designed to hold a high volume of ice in the bin. However, they may be able to produce a few hundred pounds of ice each day. Operators who allow customers to prepare their own drinks will want to consider an ice dispenser, as it can be unsanitary and impractical to allow guests to scoop ice out of a bin. For establishments that have installed popular machines that provide customers with multiple drink options, a countertop ice maker can be used to supplement the demand for ice during peak hours.

To meet high-volume dispensing needs, some ice machine heads can be paired with separate countertop dispensers. This type of ice cube machine can also be beneficial to businesses with waiting rooms or break rooms, such as healthcare facilities and office buildings.

Undercounter ice cube makers feature a combined ice machine and bin, providing ice production and storage in a compact design that can be installed in otherwise unused space under a countertop. With models that can produce less than 100 to more than 350 pounds of ice per day, this type of ice machine can help satisfy a commercial kitchen's ice demand in a small equipment footprint. It can also be installed behind a bar to help bartenders and servers keep up with beverage service.

Ice machine heads and bins can be purchased together or separately, so you can match the ice machine head you want with an ice bin that best fits your business's demands. Depending on the model you choose, ice cube makers like this can provide more than 1,000 pounds of ice per day. This can be especially useful in busy restaurants and other foodservice operations that need to keep up with high-volume demand during peak service hours. Ice machine head-and-bin units are floor models, so operators hoping to use them will need to dedicate horizontal and vertical space to the units.

If you have a prep or serving area that isn't conveniently located near your ice maker, such as at the opposite end of a long bar or in catering applications, you'll want to invest in ice maker accessories to improve your workflow. Bar ice bins are designed to be permanently installed as floor models or countertop units; ice can be brought to the bins with ice totes. Ice caddies are mobile units, which means they can be filled at the source and then wheeled to where they are needed. Ice scoops are necessary tools for safely transferring ice from one container to another, whether it is from the ice maker bin to a caddy or from the bar bin to a glass.

Cube Ice Machine Installation & Maintenance

When choosing your ice cube maker, you'll have to decide between three condenser types: air-cooled, water-cooled, and remote. Air-cooled units are the most common, but water-cooled and remote condensers can be suitable for certain operations. Remote ice machines are more complicated to install and may not be ideal for use in hot climates, but do remove the heat and noise generated by an ice maker from the kitchen. Because they require immense amounts of water and can run up the utility bill, water-cooled ice makers are usually only recommended for establishments that have a water cooling tower. Like remote units, they don’t produce the noise and heat of typical air-cooled units, and are the most efficient of the three, providing the maximum output capacity ice makers are rated by.

When installing your ice maker, it's important to make sure the machine is given the recommended amount of clearance on the sides and back. Before purchasing a unit, verify that the space in which you plan on installing the ice machine provides for that additional space, which may be several inches in either direction, and that your kitchen can provide the appropriate utilities, including electricity and water connections.

As with any piece of kitchen equipment, ice cube machines require routine cleaning and maintenance. Pairing your machine with an ice maker water filter will help your machine produce purer ice, and can also prevent the buildup of limescale caused by minerals in untreated water. Performing routine cleaning according to the manufacturer's instructions, which can include running the machine's built-in clean cycle or using ice maker cleaner for a more thorough cleaning.