Find the Best Fryer for Your Commercial Kitchen

The concept of a fryer is simple – oil is held in a pot and heated to a specific temperature in order to cook food submerged in it. As simple as it sounds, there are many variables that can impact how the equipment is used and the quality of the resulting food, including the type of heating elements or burners, the shape of the pot, and the power source, just to name a few. Different designs are best used for specific applications, and answering a few questions can help you narrow down your options so you're able to select the best commercial deep fryer for your needs.

- What are you frying?

- Do you need gas or electric?

- What size do you need?

- Will a specialty fryer work for you?

- What features will benefit your operation?

- What accessories do you need?

- How should you clean and maintain your fryer?

What Are You Frying?

The answer to this question will help you decide the type of pot you need. The determining factor is how the food is prepared: breaded (dry coating) or battered (wet coating). More sediment comes off breaded food as it is cooked, while battered foods release less sediment but often need the ability to float freely, requiring a flat bottom to avoid sticking. The design of the frypot dictates where sediment goes and what happens to it, which has a bigger effect on your food than you might expect.

The shape of the vat determines whether the fryer has a cold zone. The cold zone is an area of the pot filled with oil that isn't heated to cooking temperatures, allowing sediment to settle there without burning. This is a desirable feature for most operators, as burned breading, batter, and small pieces of food will taint the oil they’re in, which can ruin the flavor of your foods. Because the oil is generally the most expensive aspect of operating a fryer, replacing it because of burnt food gets costly quickly. However, the cold zone itself also must be filled with oil, so buying a unit with a larger cold zone than you need can also cost more money than necessary. Consider the following fryer types to help you achieve the perfect balance.

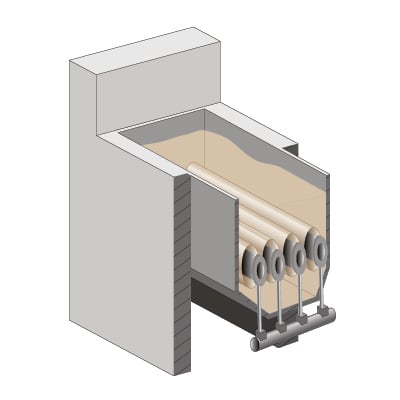

Tube-type Frypots

Best for: Breaded foods that produce a high amount of sediment.

Pros:

- Energy efficient

- Versatile

- Large cold zone

Cons:

- Difficult to clean

- Heat baffles are prone to failure in economy models

- High percentage of pot's oil is used in cold zone

A tube-style frypot has, as its name suggests, a series of tubes running through the oil near the bottom of the vat. These tubes are welded into the frypot and house gas-fired burners. Because these tubes are submerged in oil, these models offer even heat distribution and good energy efficiency due to the large heat transfer area. These tubes also hold baffles meant to help ensure maximal heat transfer, but those baffles have a tendency to weaken over time and crumble in low-end models. That can lead to more heat going up the flue and more gas being used to heat the oil.

Tube-style frypots are the most versatile type of restaurant deep fryer available, making them ideal for operators who fry a variety of items. The large cold zone makes tube-style fryers suitable for high-sediment items like breaded fish and cheese sticks, while helping prolong the life of the oil. However, the tubes make the cold zone below harder to reach, making the cleaning process more difficult and time-consuming.

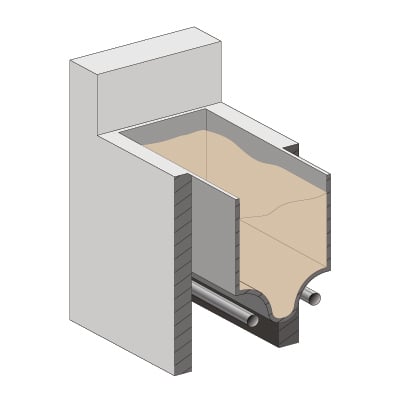

Open-pot Frypots

Best for: Low-sediment products such as french fries, hash browns, and frozen foods.

Pros:

- Easy to clean

- More reliable burner design

- Less oil dedicated to cold zone

Cons:

- Less energy efficient

- Lower sediment capacity

Open-pot fryers have no tubes or burners in the oil, leaving the bottom wide open and easy to clean. On most open-pot models, the frypot narrows into a "V" shape at the bottom, making the cold zone smaller than on a tube-style pot. This means that this style can handle less sediment than the tube-style pot, but also uses less of its oil in the cold zone.

Open-pot fryers are almost always gas-powered, with a heating element pressed to the outside of the frypot just below where it begins to narrow. Because the heating element is outside the pot, it is less energy efficient than the tube-type pots, but also experiences lower rate of failure because it doesn't require baffles.

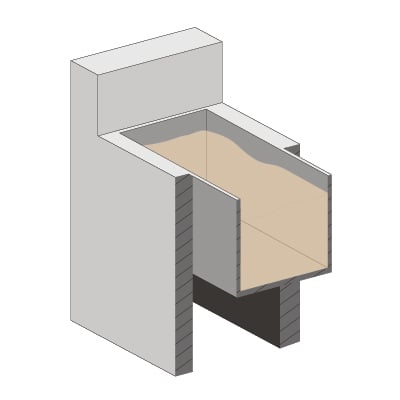

Flat-bottom Frypots

Best for: Foods coated in or made of wet batter or dough, such as doughnuts, funnel cakes, tempura, onion rings, and battered fish and chicken.

Pros:

- Works well for battered foods

- Allows foods to float freely without getting stuck

- Available in gas and electric models

Cons:

- No cold zone means sediment burns quickly

- Not suited for high-volume frying

- Can be difficult to clean and need frequent filtering

Flat-bottom fryers are shaped as their name suggests – a large rectangular space with a flat bottom. Heating elements are positioned underneath the bottom of the frypot, using the entire surface as a heat transfer area. When wet-battered items are placed into the oil, they first sink to the bottom, then rise to the surface as they cook. Flat-bottom fryers often do not use baskets, with items instead allowed to float to the top to be skimmed off as they finish cooking. The flat bottom of this type of fryer allows battered items to sink as they cook without sticking to the bottom of the basket or frypot.

Because flat-bottom fryers do not have cold zones, any sediment that falls off of cooking food will continue to cook, which can lead to the oil taking on a burnt flavor if too much sediment is produced. Due to this design, this type of fryer is not good for breaded items. Because they are well-suited to doughnuts and funnel cakes, these fryers are common in concession stands and food trucks.

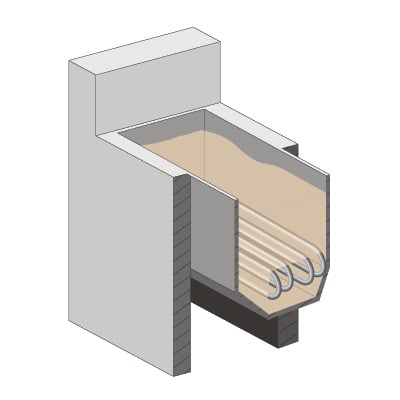

Electric Burner Frypots

Best For: Operators who want less heat vented into the kitchen, fast recovery, and for locations not set up for gas.

Pros:

- Quick recovery

- Energy efficiency

- Lift-out burner models are easy to clean

- Available in countertop models

Cons:

- Can be more expensive to operate, depending on location

- Stationary burners are difficult to clean

Electric fryers usually have cold zones below the burners, with the sizes of those varying by model. The electric elements can make this area difficult to access for cleaning, so some electric fryers offer lift-out elements that swing up on a hinge. This allows easy access for cleaning both the cold zone and the elements themselves of any burned-on food.

Do You Need Gas or Electric?

Once you know which frypot style you need, the next step will be to determine what is going to power your fryer. For some operators, the choice is simple – if prices for gas or electricity are exceedingly costly in your location, it will make sense to go with the cheaper option. Nationwide trends have gas prices declining and electricity prices rising as of 2016, but those prices vary greatly by region, so check with your local utility companies for a more accurate estimate of what prices to expect.

When deciding which heat source to use, you must also consider how that will affect the design of the unit. As explained above, open-pot and tube-style frypots are only available in gas-powered models. Electric fryers most often have their burners submerged directly in the oil, which ensures a more efficient mode of heat transfer. However, this design also makes this fryer type difficult to clean on models that aren't set up to allow the burners to swing up out of the oil.

To help you decide whether gas or electricity will work best for you, consider the following advantages of each type:

Benefits of Gas-Powered Fryers:

- Some gas-powered equipment will not be affected by power outages

- More frypot shape options

- Gas power is available in most commercial kitchens

- Because they are more common, employees are more likely to be familiar with the operation of a gas fryer

Benefits of Electric Fryers

- Simple to install thanks to fewer required connections

- No concern of gas leaks

- More efficient heat transfer due to submerged burners

- Faster recovery than most gas-powered fryers

- No interior heat baffles to fail inside the burners

- For smaller models, electric fryers are much more portable

What Size Do You Need?

To determine the size of fryer you need, you should consider both the space you have for the fryer and the amount of food you plan on frying. Fryers are available in countertop and drop-in models for kitchens that don’t have much floor space, but these have limited oil capacities. Most countertop models are electric, but some gas units are available.

Full-size commercial deep fryers are available in gas and electric, and typically have more options and special features than countertop models do. These are available in widths as narrow as 15 inches, but many require larger footprints. Because of the heat these put off, they will require clearance from combustible surfaces. With the exception of ventless models, these will need to be positioned under a hood.

Fryer output is generally calculated as 1.5 to 2 times the equipment's oil capacity per hour. For example, a fryer with a 10-pound oil capacity would be expected to put out 15 to 20 pounds of food per hour. Because countertop units are smaller than full-size models, they also have limited oil capacities, meaning they will not be able to cook as much food as their larger counterparts. Countertop fryers have oil capacities ranging from 6 to 47 pounds. Oil capacities for floor models range from 15 to 150 pounds, and can be built into batteries for high-volume frying.

Will a Specialty Fryer Work for You?

If you will fry certain types of foods, like funnel cakes and corn dogs, a specialty fryer may be the best choice for you. Consider the options below to see if a specialty fryer may meet your needs.

Funnel cake fryers are wide and shallow, with flat bottoms to accommodate the free-floating cooking style of their namesake food. These are available in gas or electric and in countertop and floor models. Funnel cake fryers are rated by "cake capacity," the number of funnel cakes they can cook at once, though manufacturers differ on whether the fryers should be rated in 8- or 9-inch cakes.

Corn dog fryers are designed to cook one type of food only, with narrow frypots and clips to hold the corn dog sticks. These are most commonly electric, but are available in electric. Most models hold 12 corn dogs at a time, though fryers specially made for foot-long corn dogs hold fewer.

Commercial pressure fryers keep the vat under pressure, which raises the temperature at which water boils. This means that less moisture is removed from the product, resulting in a juicier finished product. These are used by well-known national chains to make bone-in fried chicken, and are available in electric or gas with oil capacities as great as 75 pounds. Pressure fryers can cook food equal to about 1⁄4 the weight of the oil in each batch, so a fryer with a 48-pound oil capacity can cook about 14 pounds of product per batch.

What Features will Benefit Your Operation?

Commercial fryers have been innovated in countless ways to make operating them safer and more profitable. Some of the features below are standard on some models, but you will need to add others you want as upgrades. Consider how your fryer will be used and who will using it to decide which features will benefit your operation.

- If you do not have a hood or have no free space under yours, a ventless fryer, which has a built-in hood to remove fumes, may be a good option for you. These are capable of removing harmful fumes, vapors, and heat on their own to help you meet health and fire codes without the installation of a costly hood.

- A built-in filtration system can equip you to easily double the life of your oil by making filtering your cooking oil easier. That can help you lessen the high cost of replacing oil and prevent your food taking on a burnt taste. Built-in fryer oil filters make that cleaning process simple, often only requiring a button press, so employees are more likely to follow through with filtering the oil on schedule.

- For every 100 pounds of food cooked, you will lose between 7 and 10 pounds of your oil through absorption by the food and spillage (or drag out. To avoid having to constantly add oil, you can get a fryer with an automated top off system that will add oil as needed, saving you time and ensuring consistent cooking results.

- Basket lifts can help maintain product consistency by automatically lifting baskets out of the oil when the cooking time has ended. In addition to lowering labor costs, this feature also helps prevent product waste by eliminating a step that can result in burnt food as a result of operator error. However, operators should remove the cooked food from the basket lifts as soon as possible to get the best results.

- Another feature that can help reduce user error is programmable controls. These allow you to set up recipes including temperatures and cook times, helping prevent burnt or undercooked food.

- Often built into models with programmable controls, melt cycles use a slow heat-up process to melt solid shortening gradually. This can help extend the life of the oil by avoiding overheating of the oil as it melts.

- Split-pot models have the pot separated into two sections to prevent flavor transfer from foods with strong tastes, like fish and certain vegetables.

- Dump stations are available as accessories sold separately or built into some models. These use heat from above or below to keep fried products warm and crispy, while a crumb tray allows broken pieces or sediment to fall out of the food.

- Energy efficient fryers are available in gas or electric, and are designed to make more efficient use of its power source, saving you money in utilities. Look for the ENERGY STAR logo to show which fryers have been certified by the organization as high efficiency.

What Accessories Do You Need?

Having the right fryer accessories can make using and cleaning your fryer easier. Most models come with fryer baskets, but additional or higher-quality baskets can be purchased. Baskets in specialty shapes are available as well, such as those made for frying folded-over or bowl-shaped taco shells. Fry dump stations help you prepare for rush periods and increase product volumes, and a french fry scoop can easily scoop fries into serving containers.

Fryer screens will catch large pieces of sediment to extend times between oil filtering. Screens are available in flat designs with and without handles, and in designs shaped to accommodate split-pot and open-pot fryers. Deep fryer covers can also help extend the time between cleanings by protecting your oil from dust and debris when the fryer isn't in use. If your restaurant deep fryer doesn't come on casters, you can add some to make the unit easier to move when cleaning is needed. Unless your fryer will be part of a cook line behind a curb, we always recommend a unit with casters. If your fryer is mobile, use a quick-disconnect gas connector to make moving it for tasks like cleaning underneath it easier.

Fryer cleaning supplies are some of the most important accessories to have on hand. If your fryer does not have built-in filtering, a fryer filter can greatly extend the life of your oil. Most filters are capable of fitting under floor-model units, but check the measurements of the two pieces of equipment against each other to be sure. These can operate on suction or use gravity, with oil capacities ranging from 50 to 210 pounds. While cone filters are available for manual filtering, fryer filters provide a much safer means of cleaning oil, limiting the risk of spills and burns, as oil must be filtered while it is warm. Fryer powder is also available that can bond with small sediment to ensure it’s captured by the filter paper. Fryer brushes and clean-out rods help users dislodge sediment that can occasionally clog the drain.

When you need to get rid of used oil, a shortening disposal unit holds the oil as you move it to a containment vat for pick up by a waste management company. This equipment is mounted on wheels to provide easy transport. Like a fryer filter, a disposal unit can work with suction or gravity, and will have a capacity as high as 150 pounds. These can add an extra element of safety to disposing of oil and make transporting it much easier.

How Should You Clean & Maintain Your Fryer?

The most important part of maintaining your fryer is filtering the oil and keeping the fryer clean. Both of these steps will have a direct impact on the flavor of the food your fryer produces and the lifespan of your costly cooking oil. For most locations, the oil will need to be filtered about once a day, but high-volume frying may necessitate filtering much more often. Usage will also determine how often cleaning is needed.

High-heat gloves, an apron, and protective goggles are recommended for cleaning a fryer, as well as when filtering the oil if you are using a filter cone. Oil must be filtered while still hot, because it will coagulate as it cools. However, you do not want to have the burners going while you filter the oil, as this can cause fires and warping of the frypot. If you are removing the oil manually, you will need to attach the drain valve extension to the drain, then slowly open the valve to avoid an initial splash of hot oil.

After the unit is emptied of oil, follow the steps below to clean your fryer:

- Locate the thermostat probes in the frypot. There will generally be one for temperature settings and one used for high-limit regulation, which will shut off power to the burner or heating element if the oil exceeds a preset temperature. These are relatively fragile and can easily become broken or lose their calibration if they are banged with scrub brushes. Note their locations so you can be especially careful when cleaning around them.

- Use a fryer brush to scrub as much sediment as possible off the bottom and walls of the fryer. These brushes are usually cylindrical with a bend at the bottom, allowing you to scrub the undersides of burner tubes when needed. Because this brush type is small, a larger heat-resistant scrub brush may be preferred for cleaning large surfaces, like the sides of the frypot.

- Make sure the valve is closed, then fill the frypot halfway with hot water, with at least as much water as needed to cover any burner tubes or heating elements. Once the frypot is halfway full, add your preferred cleaning solution, either in liquid or solid pucks.

- Set thermostat to 350 degrees Fahrenheit and allow the solution to boil for 15 to 20 minutes.

- Turn thermostat off and place a vessel under the drain valve extension. Slowly open the drain valve to allow the water to drain out.

- Rinse the frypot thoroughly with clean, hot water with the drain open, allowing the water to drain into a receptacle or a nearby floor drain, if available.

- Use a clean, dry towel to dry out the frypot

- Refill frypot with oil and place a cover over the pot until it is ready to be used.

While there isn't much extensive maintenance that needs to be completed on commercial fryers, it can pay to know the most common causes of fryer malfunction. Gas tube-type fryers come with baffles inside the tubes, but those can fail, disintegrating over time under the intense heat they must withstand. One way to identify when this has happened is by measuring the heat going up the flue. Because there is nothing slowing down the flame going through the tubes, more of the heat will make it to the end of the tube and go up the flue. Slow recovery times and high flue temperatures are both indicators that your tube baffles are gone. In some cases these baffles can be replaced, but on most models this will mean the fryer should be replaced.

Thermostats are also a common failure point in fryers. If your high-limit safety is tripped repeatedly, the burner will not light, or the oil does not get hot enough, the thermostat may be at fault. These can be replaced, often without the help of a service technician, though you should always check to see if your unit is still under warranty before performing any service yourself.